Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Nota: This feature may not be available in some browsers.

Je gebruikt een verouderde webbrowser. Het kan mogelijk deze of andere websites niet correct weergeven.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

KJ66 Conversies

- Topicstarter Gerald Rutten

- Startdatum

hoi gerald

ik ben het niet helemaal met je eens dat zilverstaal niet een geschik materiaal is

ik draai al jaaren met een zilverstaale as ongehard

maar er zij ook van die dingen als een scherpen hoek die voor een kerf kan zorgen en dan maakt het ook niet uit wat voor mat je gebruik en dan vraag ik me af of dat ongeval niet iets is van onkunde

want je moet je hoeken wel afronden was dat gebuurt met die as?

want als je bij wren op de tekenigen van de as kijk staat er 90graden zonder radius

dan heb je wel kans op kerf werking

en zilverstaal harden moet het eerst kers rood worden ander kan je het niet harden en het is ook niet koud hardent zo als rvs

mvg limme

ik ben het niet helemaal met je eens dat zilverstaal niet een geschik materiaal is

ik draai al jaaren met een zilverstaale as ongehard

maar er zij ook van die dingen als een scherpen hoek die voor een kerf kan zorgen en dan maakt het ook niet uit wat voor mat je gebruik en dan vraag ik me af of dat ongeval niet iets is van onkunde

want je moet je hoeken wel afronden was dat gebuurt met die as?

want als je bij wren op de tekenigen van de as kijk staat er 90graden zonder radius

dan heb je wel kans op kerf werking

en zilverstaal harden moet het eerst kers rood worden ander kan je het niet harden en het is ook niet koud hardent zo als rvs

mvg limme

Laatst bewerkt:

Ha ha, hey Limme, kwist wel dat je hierop zou reageren....

Voor zover ik begreep was dat incident niet echt aan shear-in/inscheuring te danken tgv een scherpe hoek en was de betreffende persoon wel degelijk bekwaam. Maar ik weet ook als iedereen dat één incident lang niet meteen alles zegt, meerdere oorzaken kunnen meespelen en zolang er geen forensisch onderzoek is gedaan kun je daar inderdaad moeilijk gelijk een conclusie aan verbinden.

Los daarvan ben ik wel helemaal overtuigt door het uitleg van enkelen die er mijns inziens wel een beetje verstand van hebben, ik ga dat risico hoe dan ook helemaal niet opzoeken, zéker gezien het feit dat ik mijn turbines erg veel gebruik en dat het dan wel eens een kwestie van tijd zou kunnen zijn.

(Zelfde als je elke dag met 140km/u over de A2 scheurt (s'nachts dan wel... ) is niet kwestie van óf je bekeurd wordt maar meer kwestie van wanneer..)

) is niet kwestie van óf je bekeurd wordt maar meer kwestie van wanneer..)

Nogmaals ik ben hier niet de metaal deskundige en leer graag van andere opinies.

Voor degene die erg geintereseerd in het hele verhaal zijn, hieronder een quote vanuit dat forum. (Normaal niet chique om dat vanuit een "members only" forum te doen maar voor veiligheid vind ik dit niet geheel ongepast) Het is een heel verhaal in engels maar eigenlijk een "must know" onder de hobby bouwers.....

Voor zover ik begreep was dat incident niet echt aan shear-in/inscheuring te danken tgv een scherpe hoek en was de betreffende persoon wel degelijk bekwaam. Maar ik weet ook als iedereen dat één incident lang niet meteen alles zegt, meerdere oorzaken kunnen meespelen en zolang er geen forensisch onderzoek is gedaan kun je daar inderdaad moeilijk gelijk een conclusie aan verbinden.

Los daarvan ben ik wel helemaal overtuigt door het uitleg van enkelen die er mijns inziens wel een beetje verstand van hebben, ik ga dat risico hoe dan ook helemaal niet opzoeken, zéker gezien het feit dat ik mijn turbines erg veel gebruik en dat het dan wel eens een kwestie van tijd zou kunnen zijn.

(Zelfde als je elke dag met 140km/u over de A2 scheurt (s'nachts dan wel...

Nogmaals ik ben hier niet de metaal deskundige en leer graag van andere opinies.

Voor degene die erg geintereseerd in het hele verhaal zijn, hieronder een quote vanuit dat forum. (Normaal niet chique om dat vanuit een "members only" forum te doen maar voor veiligheid vind ik dit niet geheel ongepast) Het is een heel verhaal in engels maar eigenlijk een "must know" onder de hobby bouwers.....

Ik vroeg of het uitmaakt om het materiaal dan maar niet door en door te harden wat wat mogelijk is door het maar een oppervlakte behandeling te geven;Well done on your development work. You have done an excellent job in gettting your engine up and running so well.

Could I perhaps however offer a word of caution over the choice of silver steel for the shaft.

Whilst I agree that silver steel has, at face value, many admirable quality that would suggest it would make a suitable alternative material for shaft construction, you may be overlooking a couple of very important factors.

The advantage of EN24T is not just its hardness or wear resistance, both of which are perhaps exceeded by silver steel, but it is the chracteristic of impact resistance and ductility in EN24T that makes it the most suitable material.

As you know, the GTBA has been around since 1995 and during the intervening years many members have experimented with many different material during their pursuit of the 'perfect design'.

Shafts are particularly difficult components to get just right. If the material is too hard it will typically result in significant and uncontrolable reasonance (it will ring like a bell) unless the shaft dimensions are adjusted to account for the particular material's reasonant frequency. Typically the harder the material the stronger it will ring.

Impact resistance is a very desirable characterisatic and silver steel, which as you know is a high carbon steel, once hardend will become more brittle than EN24T with the significant increase in the likely chance of failure, particularly at the turbine hub where the shaft is shouldered and most vulnerable.

Remember that the thermal cycle of each run will adjust the hardness and temper of the shaft, particularly at that all critial shoulder at the turbine boss.

As an example of shaft experimentation, a few years ago one of our members learned to his cost that a brittle shaft is detrimental to all in the visinity. On that occasion the shaft sheared right at the turbine boss for no apparent reason at full throttle and the turbine came clean out of the back of the engine and made a very impressive score straight across the bonnet of his car, which was parked more than 50 feet away from where he was testing the engine.

Over the years, most materials have been tried, including mild steel, high carbon steels, stainless steels and even titanium all with varying levels and degrees of failure but as yet no one has managed to find a material more suitable than EN24T for this particular component.

I don't like to stiffle experimentation but I would also prefer to advise people to avoid problems that have already been resolved.

It is a quite a difficult question to answer specifically, as the point of greatest stress is the smallest diameter of the shaft, which is situated in the most vulnerable enviroment in terms heat cycle and mechanical stress.

However let's look at the two materials, EN24T and Silver Steel, and see how they compare:-

EN24T is an Alloy Steel where as Silver Steel is a high carbon steel, similar to tool steel.

Typical analysis of EN24T is:-

__C_______Si_______Mn_______Ni________Cr_______Mo

0.40%____0.30%___0.60%____1.50%____1.20%____0.25%

Typical analysis of Silver Steel is:-

__C_______Si_______Mn_______Ni________Cr_______Mo

1.00%____0.30%___0.35%____0.00%____0.40%____0.00%

Instantly you can see the Nickel / Chrome content of EN24T gives a good clue to the high temperature, high tensile strength characteristics ( these are also the primary alloy elements of Inconel ).

EN24 is described as a high quality, high tensile, alloy steel . Usually supplied readily machineable in ‘T’ condition, it combines high tensile strength, shock resistance, good ductility and resistance to wear.

Silver Steel is described as a high carbon steel usually supplied in precision ground bar form. Silver Steel is usually supplied in the annealed condition having an average hardness of 270 brinell (Rockwell C27). To obtain full wear resisting hardness with toughness silver steel may be heat treated up to a maximum hardness of Rockwell C64.

( toughness should not be mistaken for tensile strength )

The significant difference here is that EN24T is high tensile where as Silver Steel is basically just very hard - These characteristicas are not mutually interchangable or compatible.

If we look at the heat treatments characteristics of the two materials

EN24T

Hardening:

Heat uniformly to 823/850°C until heated through. Quench in oil.

Tempering:

Heat uniformly and thoroughly at the selected tempering temperature, up to 660°C and hold at heat for two hours per inch of total thickness. Tempering between 250-375°C in not recommended as this can seriously reduce the steels impact value.

Stress Relieving:

Heat slowly to 650-670°C, soak well before cooling the EN24 tool in a furnace or in air.

Silver Steel

Hardening:

Heat uniformly to 770/780 °C until heated through. Quench in water. Sizes up to 5/16” dia Silver Steel may be oil hardened from 800/810°C.

Tempering:

Heat uniformly and thoroughly at the selected tempering temperatures and hold at heat for an hour (minimum) per inch of total thickness.

Stress Relieving:

None

Proably the interesting issue here is that Sliver Steel does not have a reliable stress relief regime.

Now looking at the Mechanical Properties of EN24T

____________Tensile_______Yield_______Hardness

__Heat______Strength______Stress_______Brinell________Size

Treatment___Rm N/mm²___Re N/mm²____rp0.2 HB_______mm

___T_______850/1000______654________248/302___>150≤250

___T_______850/1000______680________248/302____>63≤250

___U_______925/1075______755________269/331____>29≤100

___V_______1000/1150_____850________293/352____>13≤63

___W______1075/1225______940_______311/375______>6≤29

___X______1150/1300_____1020_______345/401______>6≤29

___Z_________1550_______1235_________444_______>6≤29

I have not included the impact resistance values of EN24T due to lack of column space and the fact there is no corresponding value for silver steel. Actally there are very few corresponding characterisitics for silver steel other than its hardness.

These are the Mechanical Properties of Silver Steel

Tempering °C________HRc ______HB

___120____________65/63_____683/652

___150____________64/62_____683/652

___200____________62/61_____652/627

___250____________59/58_____600/587

___300____________56/53_____561/524

___350____________54/53_____536/524

___400____________50/58_____587/488

As you can see, even when Silver Steel is fully tempered it is significantly harder than any heat treated EN24 and even in its annealed supplied form is only just in the same ball park as EN24T.

The tensile strength of Silver steel is around 750 N/mm², which is significantly weaker than EN24T.

As you can see from the above, the two materials both have very admirable characteristics but are clearly different and intended for different purposes.

The most vulnerable point on a shaft is the shoulder at the turbine end, where you only have typically 6mm of material. Tensile strength, heat resistiance and impact resistance are all highly important at this point.

Remember that Silver Steel is also know as Piano Wire, often uses for model under carriage leg components. I am sure we have all have found how easy it is to fractured piano wire when trying to make under carriage components. If we consider that the part of the shaft at the shoulder where the turbine is seated is no bigger than an under carriage leg then may be this gives a good clue as to the vulnerablity of that part of the shaft.

Considering the heat cycling that is typical of an operation shaft at that most vulnerable point, I do not believe there is any surface or heat treatment that would overcome the significant differences between the two materials basic characteistics to make the use of Silver Steel a viable and safe option for a model gas turbine shaft.

Just briefly going back to the story of the sheared shaft and the turbine wheel that skipped across the car bonnet. The final resting place of the turbine was never found but judging by the damage to the car bonnet it will have gone a considerable distance further!

If you use the shafts that you have made then can I recommend extreme care about where you run them.

I am not saying that they will fail for certain but the chances of failure are significantly higher than the same shaft made from EN24T.

Very best regards

James

Hoi gerald

Ben het zeker met je eens dat er beter materialen zijn

maar ik zie nergen kragten berekeningen of verdere onder bouwing waar om zilverstaal niet zou kunnen het gaat hier om gehareden assen

maar ik ben wel met je eens na dat ik dit weet!!

volgende keer geen zilverstaal tenemen maar EN24T

maar ik ben niet van over tuigt dat zilverstaal het niet aan kan

mvg Limme

Ben het zeker met je eens dat er beter materialen zijn

maar ik zie nergen kragten berekeningen of verdere onder bouwing waar om zilverstaal niet zou kunnen het gaat hier om gehareden assen

maar ik ben wel met je eens na dat ik dit weet!!

volgende keer geen zilverstaal tenemen maar EN24T

maar ik ben niet van over tuigt dat zilverstaal het niet aan kan

mvg Limme

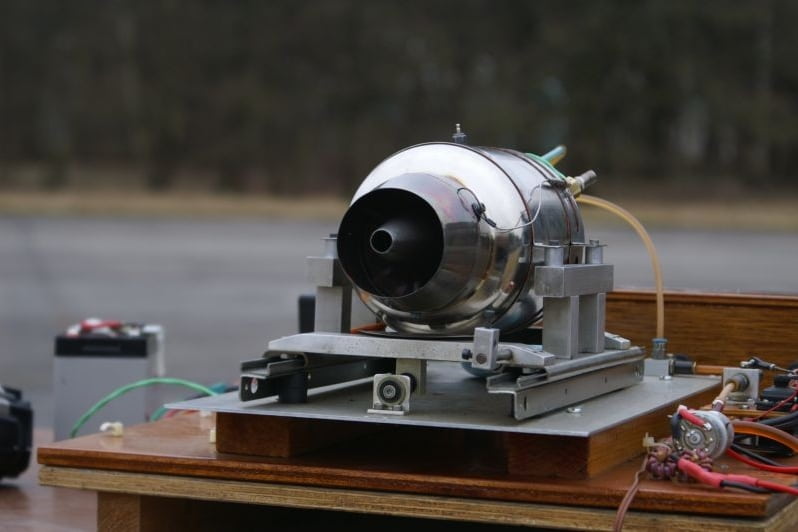

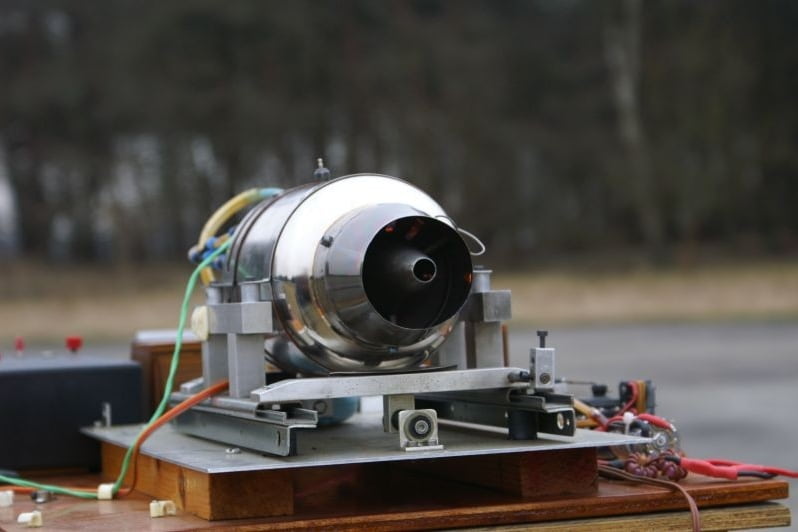

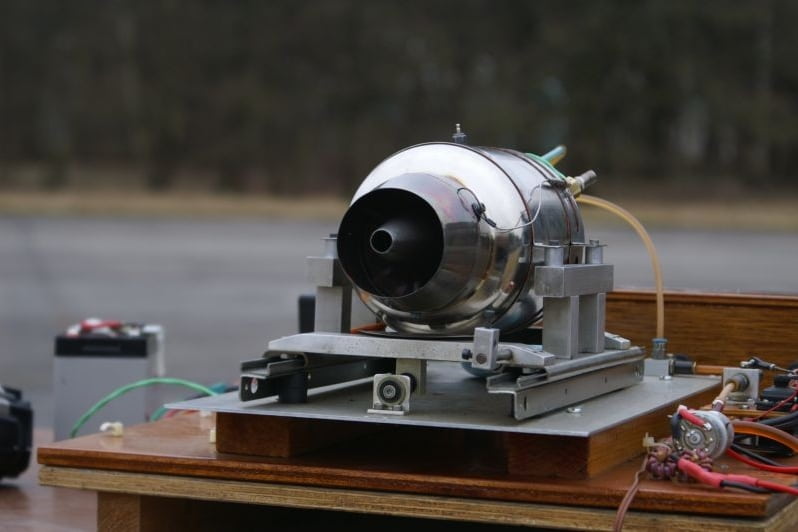

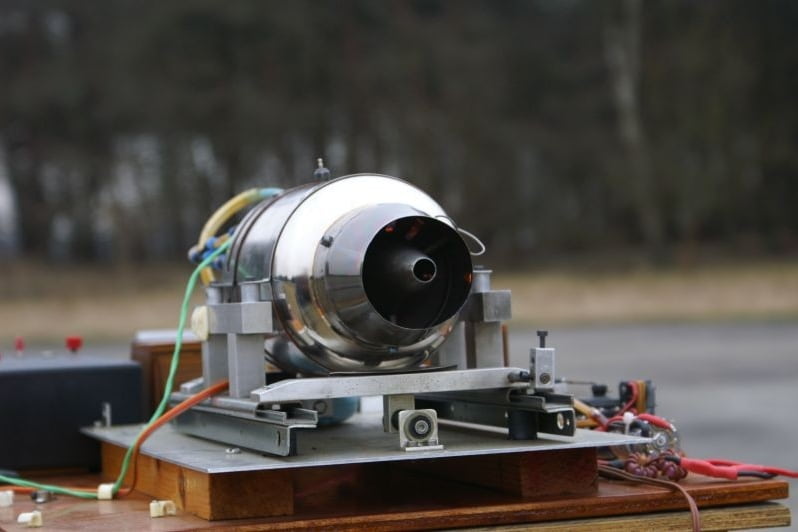

Zo, het heefd effe geduurd maar vandaag eindelijk weer eens test tijd!

Heb een nieuwe lagertunnel gemaakt met betere lagerpassingen waarbij achter vrij strak zit nu. Ook heb ik aan de achterzijde wat verbeterde lucht stroming gaatjes toegevoegd om het achterlagerhuis bij max power/temp beter te koelen, zie foto hieronder. Onder de 6 bevestigings gaten zitten kleine 1.5mm gaatjes. Deze komen uit in een luchtsleuf achter in de tunnelflens gedraaid. Via een wirwar komt de lucht uiteindelijk eruit via 6x 1.5mm gaatjes in het ngv:

Dit heefd er onder andere voor gezorgt dat de achtersectie van de aluminium tunnel koeler blijft waardoor deze minder uitzet en de lagerpassing dus beter gegarandeerd blijft. (Aluminium zet méér uit dan de stalen lager ringen) Na de eerste testen tot op 120.000rpm is het achterlager niet gaan meedraaien voor het eerst en da's erg goed nieuws! Daarnaast heb ik nu de EN24T geslepen assen die echt heél nauwkeurig zijn, zo kan ik ze echt niet maken! Kan géén slingering waarnemen met mijn klok micrometer en de passingen zijn wel zó ontzettend zuiver..... Uiteindelijk heb ik de hele rotor én lagertunnel naar Dieter Albisser gestuurd om eens extra goed uit te balanseren, kijken of er nog iets meer uit te halen is dan mijn balanceer apperaatje. Dit wil ik graag weten omdat bij het piek toerental met dit vermogen ik álles uit de kast zal moeten halen om die temp maar naar beneden te krijgen. De lange en zware compressor hoefd maar iets te hebben en dat vreet heel veel energie. Bij de kj66's maakt het minder uit omdat de compressor veel lichter én korter is wat een kleiner overhel moment geeft. Daarnaast heefd die maar het halve vermogen bij max toeren voor zijn kiezen dan dit monstertje.

Dadelijk meer.....

Groetjes,

Gerald

Heb een nieuwe lagertunnel gemaakt met betere lagerpassingen waarbij achter vrij strak zit nu. Ook heb ik aan de achterzijde wat verbeterde lucht stroming gaatjes toegevoegd om het achterlagerhuis bij max power/temp beter te koelen, zie foto hieronder. Onder de 6 bevestigings gaten zitten kleine 1.5mm gaatjes. Deze komen uit in een luchtsleuf achter in de tunnelflens gedraaid. Via een wirwar komt de lucht uiteindelijk eruit via 6x 1.5mm gaatjes in het ngv:

Dit heefd er onder andere voor gezorgt dat de achtersectie van de aluminium tunnel koeler blijft waardoor deze minder uitzet en de lagerpassing dus beter gegarandeerd blijft. (Aluminium zet méér uit dan de stalen lager ringen) Na de eerste testen tot op 120.000rpm is het achterlager niet gaan meedraaien voor het eerst en da's erg goed nieuws! Daarnaast heb ik nu de EN24T geslepen assen die echt heél nauwkeurig zijn, zo kan ik ze echt niet maken! Kan géén slingering waarnemen met mijn klok micrometer en de passingen zijn wel zó ontzettend zuiver..... Uiteindelijk heb ik de hele rotor én lagertunnel naar Dieter Albisser gestuurd om eens extra goed uit te balanseren, kijken of er nog iets meer uit te halen is dan mijn balanceer apperaatje. Dit wil ik graag weten omdat bij het piek toerental met dit vermogen ik álles uit de kast zal moeten halen om die temp maar naar beneden te krijgen. De lange en zware compressor hoefd maar iets te hebben en dat vreet heel veel energie. Bij de kj66's maakt het minder uit omdat de compressor veel lichter én korter is wat een kleiner overhel moment geeft. Daarnaast heefd die maar het halve vermogen bij max toeren voor zijn kiezen dan dit monstertje.

Dadelijk meer.....

Groetjes,

Gerald

Zo, moest effe happie eten...

Na deze aanpassingen maar weer eens op stap geweest in de hoop wat meer succes te boeken, en dat ging goed! De motor klinkt goed, niets wat duid op lagerringen die meedraaien, beetje bij beetje meer vermogen en weer uitzetten om de horen of lagers het wel fijn vinden. Uiteindelijk helemaal naar 120.000 toeren gegaan en het loopt als een zonnetje, een stuk koeler dan voorheen. Bij de vorige testen had ik bij 119.000 een temperatuur van 800 graden wat alleen maar hoger opliep als ik gas er op hield, heb een keer bijna 900 gezien...tijd om te stoppen! Nu echter bij 118.000 op de 700 graden en bij 120.000 zit ik op ongeveer 730 graden, goede vooruitgang! Deze temperatuur is nog steeds niet echt koel maar hier kan ik meer mee leven. Ik heb nog wel enkele kleine truukjes in gedachten maar zo durf ik hem best de lucht in te sturen. Daarnaast heefd de motor deze temperatuur alleen bij piek vermogen, bij 110.000 zit ik alweer op 620 graden en meestal vlieg ik nog daaronder. Dit vermogen gebruik je alleen effe bij start en vertikaal recht omhoog. Trouwens hoef ik me voor deze temperaturen nergens te schamen, veel fabrikanten doen niet veel beter weet ik uit ervaring. Die temperaturen waar ze mee adverteren zijn vaak gemiddelden.

Nee, ik ben nu hartstikke blij dat ik nu al zover ben, misschien nog een beetje "tweaken" maar dat kan altijd nog. De eerste vluchten in de betreffende kist zal ik hem trouwens eerst downgraden naar 16 kg zodat ik hem eerst in de gaten kan houden. Moet je eens voorstellen, de KJ66 heefd 8kg bij 120.00 toeren terwijl deze motor er nu bijna 19kg uithaald bij hetzelfde toerental...., ik weet niet of dat nog wel koeler kan, het is een hele hoop energie wat in zo'n keteltje zit. (wat een geweld trouwens....)

Hier de krachtmeter en de fadec uitlees unit:

Hieronder nog enkele foto's tijdens het draaien. Van achteren gezien een hele mooie stabiele vlam, geen hotspots etc. Ben ook erg tevreden met de combinatie van de nieuw gekozen compressor en zelfgemaakte diffuser....daar doen we het toch voor? Thuis de motor uit elkaar en alles zat na 10 liter brullen nog steeds prima in elkaar. Lagers nog in nieuwstaat en lekker nat. Project zo goed als geslaagd, nu nog duurzaamheid door hem geregeld effe aan de tand te voelen.

Hierna nog wat experimenteren met kleine lipo accu pakketjes om ook daar gewicht laag te houden en dan beginnen aan de kist zijn onderstel.

Groetjes,

Gerald

Na deze aanpassingen maar weer eens op stap geweest in de hoop wat meer succes te boeken, en dat ging goed! De motor klinkt goed, niets wat duid op lagerringen die meedraaien, beetje bij beetje meer vermogen en weer uitzetten om de horen of lagers het wel fijn vinden. Uiteindelijk helemaal naar 120.000 toeren gegaan en het loopt als een zonnetje, een stuk koeler dan voorheen. Bij de vorige testen had ik bij 119.000 een temperatuur van 800 graden wat alleen maar hoger opliep als ik gas er op hield, heb een keer bijna 900 gezien...tijd om te stoppen! Nu echter bij 118.000 op de 700 graden en bij 120.000 zit ik op ongeveer 730 graden, goede vooruitgang! Deze temperatuur is nog steeds niet echt koel maar hier kan ik meer mee leven. Ik heb nog wel enkele kleine truukjes in gedachten maar zo durf ik hem best de lucht in te sturen. Daarnaast heefd de motor deze temperatuur alleen bij piek vermogen, bij 110.000 zit ik alweer op 620 graden en meestal vlieg ik nog daaronder. Dit vermogen gebruik je alleen effe bij start en vertikaal recht omhoog. Trouwens hoef ik me voor deze temperaturen nergens te schamen, veel fabrikanten doen niet veel beter weet ik uit ervaring. Die temperaturen waar ze mee adverteren zijn vaak gemiddelden.

Nee, ik ben nu hartstikke blij dat ik nu al zover ben, misschien nog een beetje "tweaken" maar dat kan altijd nog. De eerste vluchten in de betreffende kist zal ik hem trouwens eerst downgraden naar 16 kg zodat ik hem eerst in de gaten kan houden. Moet je eens voorstellen, de KJ66 heefd 8kg bij 120.00 toeren terwijl deze motor er nu bijna 19kg uithaald bij hetzelfde toerental...., ik weet niet of dat nog wel koeler kan, het is een hele hoop energie wat in zo'n keteltje zit. (wat een geweld trouwens....)

Hier de krachtmeter en de fadec uitlees unit:

Hieronder nog enkele foto's tijdens het draaien. Van achteren gezien een hele mooie stabiele vlam, geen hotspots etc. Ben ook erg tevreden met de combinatie van de nieuw gekozen compressor en zelfgemaakte diffuser....daar doen we het toch voor? Thuis de motor uit elkaar en alles zat na 10 liter brullen nog steeds prima in elkaar. Lagers nog in nieuwstaat en lekker nat. Project zo goed als geslaagd, nu nog duurzaamheid door hem geregeld effe aan de tand te voelen.

Hierna nog wat experimenteren met kleine lipo accu pakketjes om ook daar gewicht laag te houden en dan beginnen aan de kist zijn onderstel.

Groetjes,

Gerald

S

Sandor

Guest

das veel thrust!

goed bezig , ik denk als je de cone iets verder open maakt je temp snel omlaag gaat.

je thrust zal denk ik hetzelfde blijven..

de temp volers bij fadec moet je niet verder als 2mm erin hangen.

hierop zijn ze gecalibreerd.

als er een probleem is met de temp calibratie kan ik je die zo opnieuw afregelen.

goed bezig , ik denk als je de cone iets verder open maakt je temp snel omlaag gaat.

je thrust zal denk ik hetzelfde blijven..

de temp volers bij fadec moet je niet verder als 2mm erin hangen.

hierop zijn ze gecalibreerd.

als er een probleem is met de temp calibratie kan ik je die zo opnieuw afregelen.

mooi motortje voor in een hawk

Hey Pieter, die past daar zéker in, ik had echter iets sportievers in gedachten.....mooi motortje voor in een hawk

@Sandor, tnx, zal het in gedachten houden. Enig idee wat voor accupakket ik minimaal kan gebruiken? (manual start) Heb een hausl300 pompje en op mijn testbank zie ik 5.4volt max power, ampere meter gaat maar tot 3A maar ik vermoed ergens rond de 4,5A. Zou een dubbele lipo (7,4v) met ongeveer 1000mAh voldoende zijn voor een enkele vlucht mét reserve?

Grtz,

Gerald

H

Henri Artz

Guest

Dit is wel weer héél gaaf Gerald!!

Moet ik zien, en horen.

Groetjes,

Henri

Moet ik zien, en horen.

Groetjes,

Henri

S

Sandor

Guest

Hey Pieter, die past daar zéker in, ik had echter iets sportievers in gedachten.....

@Sandor, tnx, zal het in gedachten houden. Enig idee wat voor accupakket ik minimaal kan gebruiken? (manual start) Heb een hausl300 pompje en op mijn testbank zie ik 5.4volt max power, ampere meter gaat maar tot 3A maar ik vermoed ergens rond de 4,5A. Zou een dubbele lipo (7,4v) met ongeveer 1000mAh voldoende zijn voor een enkele vlucht mét reserve?

Grtz,

Gerald

wow das hoog welke hausl gebruik je nu?

30020SP?

ik zou wel naar deze pomp toe gaan scheelt wel wat in verbruik.

en betere acceleratie.

wat is nu je pompwaarde bij max rpm?.(sorry zie het net pas)

259 is een goede waarde eigenlijk

ieder geval je fadec gaat door totdat je accu leeg is.

ik zou persoonlijk gaan voor een 1600 mah 20C 7,4 lipootje lekker ligt en genoeg power.

ik zie wel nogal wat knel punten in je bandstof toevoer. haaks en een ball valve

geen filter achter je pomp? riskant voor je smering.

1 small messing deeltje en je smeernaald zit potdicht.

Laatst bewerkt door een moderator:

@Gerald

Oeps dat is echt een beest van een motorke, super van je, zou die passen in een Phantom ??

Lang niet meer van je vernomen, zekers allebei druk dat zal het wezen, komt goed.

Jij bent goed bezig, toppie van je

Vriendelijke groet Jaap

p/s Kijk eens naar die Kg meter, die lacht je zelfs toe.

Oeps dat is echt een beest van een motorke, super van je, zou die passen in een Phantom ??

Lang niet meer van je vernomen, zekers allebei druk dat zal het wezen, komt goed.

Jij bent goed bezig, toppie van je

Vriendelijke groet Jaap

p/s Kijk eens naar die Kg meter, die lacht je zelfs toe.

Laatst bewerkt:

Hey Henri, Gertjan en Jaap, tnx!

Ik gebruik inderdaad de 30020SP met grotere aanzuig nippel. Die haakse en andere nippels zitten enkel op de testbank, in de kist wordt alles zo kort en direct mogelijk aangesloten, scheelt inderdaad weer een paar mAh's. Ik realiseer inderdaad dat ik nog geen filter ná de pomp heb, staat inmiddels op mijn "next" lijst.

De motor gaat uiteindelijk in onderstaand beestje. Ik vind de F16 een heerlijke kist om mee te vliegen, schaal 1/5 bij 3 meter vlieg'tie nóg lekkerder. Grote uitdaging: De kist mag leeg niet meer dan 15kg wegen om mee te kunnen doen in F4C schaal klasse.....

Grote uitdaging: De kist mag leeg niet meer dan 15kg wegen om mee te kunnen doen in F4C schaal klasse..... De motor heb ik al ruim een kilo lichter dan de AMT die er normaal in gaat, next op de bouwplank is het schaal onderstel die effe langs Sonja Bakker moet

De motor heb ik al ruim een kilo lichter dan de AMT die er normaal in gaat, next op de bouwplank is het schaal onderstel die effe langs Sonja Bakker moet  !

!

wow das hoog welke hausl gebruik je nu?

30020SP?

ik zou wel naar deze pomp toe gaan scheelt wel wat in verbruik.

en betere acceleratie.

wat is nu je pompwaarde bij max rpm?.(sorry zie het net pas)

259 is een goede waarde eigenlijk

ieder geval je fadec gaat door totdat je accu leeg is.

ik zou persoonlijk gaan voor een 1600 mah 20C 7,4 lipootje lekker ligt en genoeg power.

ik zie wel nogal wat knel punten in je bandstof toevoer. haaks en een ball valve

geen filter achter je pomp? riskant voor je smering.

1 small messing deeltje en je smeernaald zit potdicht.

Ik gebruik inderdaad de 30020SP met grotere aanzuig nippel. Die haakse en andere nippels zitten enkel op de testbank, in de kist wordt alles zo kort en direct mogelijk aangesloten, scheelt inderdaad weer een paar mAh's. Ik realiseer inderdaad dat ik nog geen filter ná de pomp heb, staat inmiddels op mijn "next" lijst.

De motor gaat uiteindelijk in onderstaand beestje. Ik vind de F16 een heerlijke kist om mee te vliegen, schaal 1/5 bij 3 meter vlieg'tie nóg lekkerder.

Man man man, wat een power uit zo`n motortje.

Ik met m`n oud P80`je heb al ontzag voor die 8 kg bij 117.000 rpm en Ger zegt dat ie zelfs nog wel naar de 120.000 kan 8-O

Als ik dan die 19kg op die teller zie staan dan is dat van mij maar een baby`tje (zal nog wel door de "onervarneheid" komen, over een x aantal jaar is dat voor mij misschien ook wel normaal ;-) ).

Maar een schitterend project Gerald met geweldig mooie resultaten, we blijven het volgen

Ik met m`n oud P80`je heb al ontzag voor die 8 kg bij 117.000 rpm en Ger zegt dat ie zelfs nog wel naar de 120.000 kan 8-O

Als ik dan die 19kg op die teller zie staan dan is dat van mij maar een baby`tje (zal nog wel door de "onervarneheid" komen, over een x aantal jaar is dat voor mij misschien ook wel normaal ;-) ).

Maar een schitterend project Gerald met geweldig mooie resultaten, we blijven het volgen

E

Ernst38

Guest

Hallo,

Ik ben al een poosje met veel facinatie aan het lezen hoe hobbyisten zelf hun gasturbine's bouwen, en heb zelf ook een klein beginnetje gemaakt met een kj-66.

zou iemand mij kunnen vertellen waar ik een turbinewiel kan kopen, of laten maken.

Ik ben al een poosje met veel facinatie aan het lezen hoe hobbyisten zelf hun gasturbine's bouwen, en heb zelf ook een klein beginnetje gemaakt met een kj-66.

zou iemand mij kunnen vertellen waar ik een turbinewiel kan kopen, of laten maken.

Hoi Ernst, deze kun je het beste bij Dieter Albisser bestellen; JETMAX | Home

Deze zijn erg goed van kwaliteid wat zeker niet onbelangrijk is. Goede service en hulp als je hem mailt. Al mijn turbines draaien nu op zijn wielen.

Groetjes,

Gerald

Deze zijn erg goed van kwaliteid wat zeker niet onbelangrijk is. Goede service en hulp als je hem mailt. Al mijn turbines draaien nu op zijn wielen.

Groetjes,

Gerald