prop-er

Forum veteraan

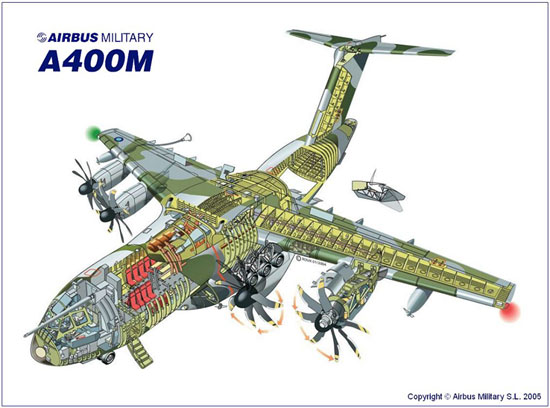

The TP400-D6 turboprop engine is the western world’s largest-ever turboprop engine chosen to power the Airbus Military A400M transport aircraft.The new-generation TP400-D6 engine has been conceived to fulfil the design requirements for the A400M military transport aircraft, Europe's response to the increasing need for military transport capacity as well as peacekeeping and humanitarian intervention around the world.

The TP400-D6 engine is a three-shaft configuration that will deliver a maximum power output in excess of 11,000shp (shaft horsepower), making it the most powerful turboprop in the Western world. It benefits from proven technology derived from the outstanding expertise in military and civil aero engines of each of our Partner Companies.

Four turboprops each rated at 11 000 shp will contribute to excellent performance characteristics which will enable A400M to transport a variety of loads and personnel over long distances at high cruise speed. Turboprops provide the optimum combination of take-off and landing performance, cruise fuel efficiency and tactical mission performance such as manoeuvring on the ground, steep descents and air-dropping.

More than 750 engines will be required for the 180 A400M aircrafts ordered by the launch Nations. Other applications may come later.

EPI benefits from the capability and the expertise of its parents companies, which are leaders in aero engines in Europe. They have guaranteed EPI an international network and a full support of the TP400-D6 engine for their customers worldwide.

The TP400-D6 engine, which is being designed and manufactured to power the new Airbus A400M military transport aircraft, continues to undergo extensive performance and operability tests throughout Europe on EPI partners' indoor and outdoor facilities. A total of ten TP600-D6 engines will be built and tested for certification. To date, the TP400-D6 engine has logged more than 300 hours of testing

Overview TP400-D6 facts

The Engine is designed for optimum Maintainability by:

- Full module interchangeability

- Quick LRU replacement

- Dedicated on wing boroscope ports

- FADEC built-in test functions

- NBC requirements taken into account

- Engine replacement within 4 hours

TP400-D6 is tailored for A400M mission requirements:

- Cycle optimised for A400M mission performance and growth potential

- Component technology based on best in service military and commercial practice

- Proven three shaft architecture

- Moderate temperatures for long life

- Modular design for maintainability and low life cycle costs

- Meets future noise and emissions regulations

Engine Characteristics:

- Type of Engine: three-shaft turboprop

- Power output: approximately 11,000 shp at sea level

- Pressure / compression ratio: 25

- Weight: approx. 1,860kg (dry)

- Length: 3,5 m Engine overall length

Engine Architecture:

Offset Propeller Gear Box compliant with two senses of rotation for the

propeller

Intermediate Pressure Compressor

- pressure ratio 3.5

- 5 stage unit with no variables

High Pressure Compressor

- pressure ratio 7

- 6 stage unit

Combustor

- Single stage cooled High Pressure Turbine

- Single stage cooled Intermediate Pressure Turbine

- Three stage uncooled Low Pressure Turbine (Power Turbine)

The TP400-D6 will use the Ratier-Figeac FH386 propeller (Airbus Military

interface).

Laatst bewerkt door een moderator: