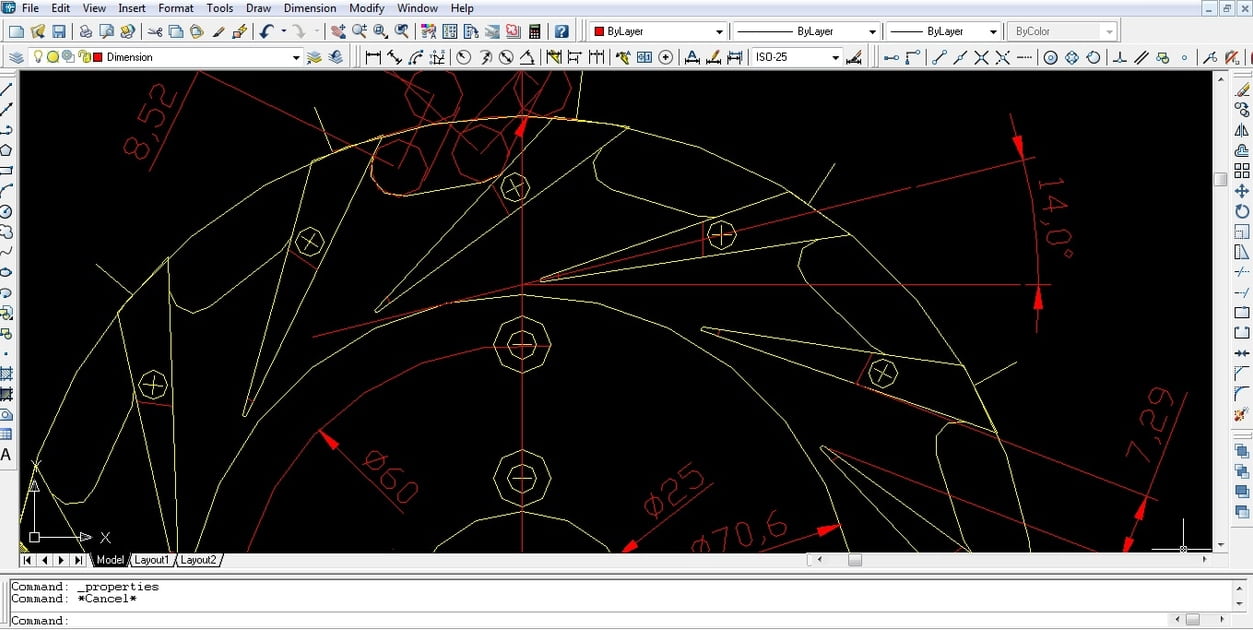

These are my thoughts, I think this diffuser with the older type compressor needs a small adjustment on the wedge angle which might be a bit flatter. All my other engines with newer aggressively retro-curved blades need a much steeper angle but these T04B compressor wheel is different. (There is no real alternative to this wheel) Also the so called "throat area" might be too large and could be a tiny bit smaller. (The 7,29 from the picture) If you could try a slightly smaller wedge angle, the 14,0 number on the picture to lets say 13,5 or even 13,0 would be better I think. This smaller angle also has the benefit that the throat will close to a more acceptable value which would be around 6,5mm.

Just my thoughts, I don't know if you can incorporate this in your built? If you are able to make them cnc you could even try both my original and this adjustment as well?