Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Nota: This feature may not be available in some browsers.

Je gebruikt een verouderde webbrowser. Het kan mogelijk deze of andere websites niet correct weergeven.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

YANGTZE RIVER HIGH-NET FISHING SAMPAN

- Topicstarter Heinrich

- Startdatum

Hello Everyone

After the bow deck planks had been installed, the end pieces for the Yuloh (rowing and steering oar) were added to both the bow and stern. The flexibility of the sampan is that it can be steered from both ends which makes it extremely maneuverable.

The red squares indicate the two platforms for the Yuloh (the steering and sculling oar). The construction of the Yuloh and its mode of operation will be discussed a little later.

PREPPING THE HULL

I could now turn my attention to sanding the hull. You will have noticed that I have not mentioned anything about that up to this point as I first wanted to make sure that the structural rigidity of the hull was good enough. With the deck planking completed and the floor in place though, the hull was as strong and rigid as anyone could wish for.

Now for interest’s sake – when I plank the hull, I do not bevel the edges of planks as they butt-up against adjoining partners. Lazy? I probably am, but that’s not the reason for not doing it.. Without beveling or chamfering, a little "lip" is created when two planks are butted-up against each other. That little “lip” that remains, provides (to me at least) the perfect angle (when viewed from the top) at which I need to sand the hull. I start by sanding cross-grain at an approximate angle of 45 degrees using "heavy artillery" 80-grit sandpaper. The Pear Wood is resilient and the 2mm thickness, meant that lots of sanding was required to remove the "lips". Once that was done, I moved down to 120-grit sandpaper and started sanding longitudinally and following the grain of the wood. Finally 360-grit was used to complete the process. The whole process was straightforward and there was nothing untoward.

YULOH

In his excellent book, "The Junks and Sampans of the Yangtze". G.R.G. Worcester wrote:

"Propulsion is by means of a single “yuloh”, or “lu”, an original and extremely efficient implement; 13 feet in length, it is scarfed in three pieces, thus forming a gentle curve. When in operation, the blade is kept very deep in the water, that is to say, 3 1/2 feet, or more than one-third of its length being below the surface, and as the face of the blade is 6 inches in width, this combination gives much increased leverage and power.

The yuloh pivots on a 3-inch bearing-pin* which ends in a knob. This pin is situated on the transom, and the loom is held in place by a coir lanyard, 5 1/2 feet long, attached to a ring-bolt in the stern deck. The hand holding the yuloh is held at head level and rather behind, while the hand on the lanyard works across the breast. It is interesting to record that the sculler can average 41 strokes to the minute under favourable weather conditions, yielding the satisfactory speed of 8

"li" (knots) per hour!

While most sampans share the exact same basic characteristics, they do, nevertheless, fall into two definite categories, known as “pang”, or groups. These are the Ning-pang, or group manned by Ningpo men, and the Soo-pang, or group manned by either Soochow men, men of Shanghai, or men from Kiangyin, a small town some 80 miles up the Yangtze.

The distinguishing feature is that in the Ningpo-owned craft the bearing-pin for the yuloh is situated on the port side, which necessitates the sculler using his left hand on the oar; while in the boats operated by Soochow, Shanghai, and Kiangyin men, the bearing-pin is on the starboard side and the sculler operates the yuloh with his right hand. The exponents of both methods maintain that theirs is the only reasonable mode of propulsion. My sampan is built according to the latter option.

*Bearing-pin: This might be confusing as it does not refer to a device which facilitates rotation, but actually means "load-bearing". In other words, it "Bears" or "carries" the Yuloh - hence me changing it the name to "load-carrying platform" and "load-carrying pin".

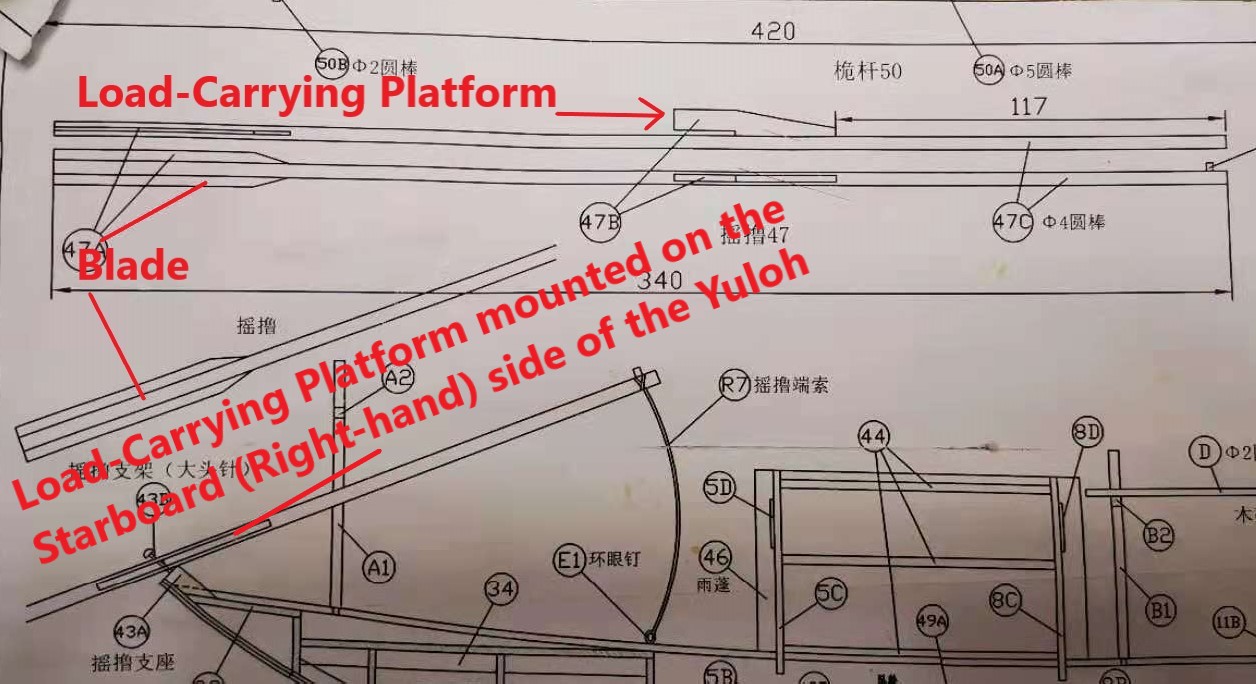

How the instruction manual shows assembly of the Yuloh.

The actual "load-carrying pin" and- "platform" as constructed on the model. Getting that platform to blend it seamlessly with the oar required patience. The slot provides the opening for sliding the platform over the pin.

The blade is constructed by pre-shaping two pieces of pear wood to the correct size and shape and then gluing them to either side of the oar. Interestingly, the blade and the load-carrying platform are at 90 degrees to reach other. So ... if the load-bearing platform is completely level on a horizontal plane, the blade has a 90-degree vertical angle.

The assembly on the model. In real model-life, that Yuloh is 35 cm long and the overall model length is 69 cm - so you can see that it is a substantial oar.

The picture below taken from one of Unicorn's test builds on the 4h forum clearly show the "operation" of the Yuloh and that this model was built according to the "Soochow" (Suzhou) / Shanghai style with the load-bearing platform on the starboard side of the oar and the right-hand higher up on the Yuloh - thus in the dominant position.

One of the smaller "Water-Taxi" sampans being "Yulohed" in Shanghai.

When I return for the next posting, it will be to show you the assembly and installation of the bamboo canopy.

Thank you all so much for looking, commenting, liking or just browsing.

Best regards - Heinrich

After the bow deck planks had been installed, the end pieces for the Yuloh (rowing and steering oar) were added to both the bow and stern. The flexibility of the sampan is that it can be steered from both ends which makes it extremely maneuverable.

The red squares indicate the two platforms for the Yuloh (the steering and sculling oar). The construction of the Yuloh and its mode of operation will be discussed a little later.

PREPPING THE HULL

I could now turn my attention to sanding the hull. You will have noticed that I have not mentioned anything about that up to this point as I first wanted to make sure that the structural rigidity of the hull was good enough. With the deck planking completed and the floor in place though, the hull was as strong and rigid as anyone could wish for.

Now for interest’s sake – when I plank the hull, I do not bevel the edges of planks as they butt-up against adjoining partners. Lazy? I probably am, but that’s not the reason for not doing it.. Without beveling or chamfering, a little "lip" is created when two planks are butted-up against each other. That little “lip” that remains, provides (to me at least) the perfect angle (when viewed from the top) at which I need to sand the hull. I start by sanding cross-grain at an approximate angle of 45 degrees using "heavy artillery" 80-grit sandpaper. The Pear Wood is resilient and the 2mm thickness, meant that lots of sanding was required to remove the "lips". Once that was done, I moved down to 120-grit sandpaper and started sanding longitudinally and following the grain of the wood. Finally 360-grit was used to complete the process. The whole process was straightforward and there was nothing untoward.

YULOH

In his excellent book, "The Junks and Sampans of the Yangtze". G.R.G. Worcester wrote:

"Propulsion is by means of a single “yuloh”, or “lu”, an original and extremely efficient implement; 13 feet in length, it is scarfed in three pieces, thus forming a gentle curve. When in operation, the blade is kept very deep in the water, that is to say, 3 1/2 feet, or more than one-third of its length being below the surface, and as the face of the blade is 6 inches in width, this combination gives much increased leverage and power.

The yuloh pivots on a 3-inch bearing-pin* which ends in a knob. This pin is situated on the transom, and the loom is held in place by a coir lanyard, 5 1/2 feet long, attached to a ring-bolt in the stern deck. The hand holding the yuloh is held at head level and rather behind, while the hand on the lanyard works across the breast. It is interesting to record that the sculler can average 41 strokes to the minute under favourable weather conditions, yielding the satisfactory speed of 8

"li" (knots) per hour!

While most sampans share the exact same basic characteristics, they do, nevertheless, fall into two definite categories, known as “pang”, or groups. These are the Ning-pang, or group manned by Ningpo men, and the Soo-pang, or group manned by either Soochow men, men of Shanghai, or men from Kiangyin, a small town some 80 miles up the Yangtze.

The distinguishing feature is that in the Ningpo-owned craft the bearing-pin for the yuloh is situated on the port side, which necessitates the sculler using his left hand on the oar; while in the boats operated by Soochow, Shanghai, and Kiangyin men, the bearing-pin is on the starboard side and the sculler operates the yuloh with his right hand. The exponents of both methods maintain that theirs is the only reasonable mode of propulsion. My sampan is built according to the latter option.

*Bearing-pin: This might be confusing as it does not refer to a device which facilitates rotation, but actually means "load-bearing". In other words, it "Bears" or "carries" the Yuloh - hence me changing it the name to "load-carrying platform" and "load-carrying pin".

How the instruction manual shows assembly of the Yuloh.

The actual "load-carrying pin" and- "platform" as constructed on the model. Getting that platform to blend it seamlessly with the oar required patience. The slot provides the opening for sliding the platform over the pin.

The blade is constructed by pre-shaping two pieces of pear wood to the correct size and shape and then gluing them to either side of the oar. Interestingly, the blade and the load-carrying platform are at 90 degrees to reach other. So ... if the load-bearing platform is completely level on a horizontal plane, the blade has a 90-degree vertical angle.

The assembly on the model. In real model-life, that Yuloh is 35 cm long and the overall model length is 69 cm - so you can see that it is a substantial oar.

The picture below taken from one of Unicorn's test builds on the 4h forum clearly show the "operation" of the Yuloh and that this model was built according to the "Soochow" (Suzhou) / Shanghai style with the load-bearing platform on the starboard side of the oar and the right-hand higher up on the Yuloh - thus in the dominant position.

One of the smaller "Water-Taxi" sampans being "Yulohed" in Shanghai.

When I return for the next posting, it will be to show you the assembly and installation of the bamboo canopy.

Thank you all so much for looking, commenting, liking or just browsing.

Best regards - Heinrich

Pingu57

Forum veteraan

Ik geniet deze bouw BAIE!

Ik ook Heinrich, en ik denk, velen met mij

Omdat we hier bij de historische zeilschepen zitten: een passend schaalvoorbeeldje?

@Mees Ippel Not to worry, Mees! De zeil kom nog!

Mooi! Apart schip en een bizar mooie bouw.

Daar was ik ook niet bang voor[emoji3] Ik dacht alleen, als je het echt te gek en afwijkend zou willen maken.........@Mees Ippel Not to worry, Mees! De zeil kom nog!

“It was God's will that they have to live on the water,

[that] they have learnt how to tread the wave from childhood.

boiling the crab as main food instead of grains,

using manila hemp instead of yarn to make garments.

children were assigned to cut the wild cane secretly,

when tides rising during spring nights

and the shallows are drown[ed].” (sic)

(Yang1,1154)

Hello Everyone

As promised in my previous posting, the bamboo canopy was next. It consisted of two main frames (each comprising of three separate sections) which are glued together and then further affixed by two overlapping sections which are appropriately curved.

The three separate sections which make up one frame and the two overlapping pieces (here unfortunately blocked by the clothes’ pegs) which lock them together. These two assembled frames are then inserted into four slots which are provided for in the top railing.

This was really an easy task and fitment of the two frames into the slots were perfect. However, here I deviated slightly from the kit plans. Have a look at the picture below

Unicorn suggests that the frames should be inserted into the slots up to the black line. The two slots directly above that line will thus stand proud of the top railing. This is understandable as there are 6 cross bars provided which slot into these six slots and which connect the two frames. However, I inserted my two frames up to the red line. This meant that my top railing would take the place of the first two bars which meant a much stronger connection and that the canopy would sit slightly deeper/lower than indicated on the plans. I was OK with this, and in the end, it turned out to be a very good move with an unexpected advantage.

Here the framework of the canopy is completed. Note the two extra spars directly in front of the framework which I did not have to use. Also notice the table in the living area. It looks very rudimentary but that is exactly what they looked like – low in height and devoid of any kind of decoration.

The installation of the bamboo canopy is an exercise in dexterity. It comes supplied in two separate, but identical sheets which needs to be glued back-to-back and then shaped to the correct form and size. This was easy enough, but then I made a mistake – I left it overnight to dry. If ever you have to work with bamboo and do something similar – use your PVA, wait an hour for it to set and while the glue is still pliable, do the bending. The problem is that once the glue is dry, those two sheets become surprisingly stiff and resist bending. Great care has to be taken that it doesn’t develop cracks in the shaping process – if that happens you are screwed, because the cracks will just get bigger and bigger.

I had two small cracks develop (ok…ok, I know…personally, I probably have many large cracks – but I’m referring to the bamboo piece now). Luckily, I did still have the bamboo sheeting from the first model. I just cut two appropriately-sized pieces and carefully glued them to the inside of the canopy where the cracks were starting to rear their ugly heads. That solved that little issue once and for all.

Next, I soaked the bamboo sheeting in water and curved it around one of my favorite objects – a Nescafe

bottle. Unfortunately, I did not take pictures of this as I was all thumbs trying to get the sheeting wrapped around the coffee bottle and securing it with elastic bands at the same time. After the bamboo had dried, it held its shape beautifully and could be glued onto the canopy framework.

bottle. Unfortunately, I did not take pictures of this as I was all thumbs trying to get the sheeting wrapped around the coffee bottle and securing it with elastic bands at the same time. After the bamboo had dried, it held its shape beautifully and could be glued onto the canopy framework.

Bamboo canopy in place. You will also notice six H-shaped frames - two at the stern and four in front of the canopy. The connecting piece on the starboard side (closest to the camera) has not yet been glued down, but has just been placed into position. The framework in front of the canopy was used for fish nets and the two “paddle oars” (different oars to the Yuloh).

Copyright by John S. Murray (I have no idea where I downloaded this picture from.)

The one at the stern was primarily used for storing the Yuloh and excess rope not in use. Both set of frames could also be used for a host of other things – anything from clothes lines to additional sheltering.

Stern framework used for the storage of the rope and as a clothes line. Note that a piece of clothing was even attached to the yuloh to dry.

This picture shows the port side paddle oar in its storage place. The reason that I have kept the right side of the framework “open” at this stage is to facilitate easier working on the rigging.

This is also where my unexpected advantage of my lower canopy panned-out nicely. Notice how nicely the paddle oar clears the canopy – exactly like it does in real life. With the canopy installed as per the plans’ suggestion, it would have been too high for the paddle oar to be mounted like that.

Now let’s take a few looks at the canopy in real-life situations.

Worcester describes the canopy as follows: “The centre part is decked, leaving a cockpit amidships which is covered with a small house made of closely woven matting arranged in three overlapping sections and painted white*. In this portion the passengers are accommodated, and actually as many as five can be carried and even more; nine, however, is about the limit.

*In all my research, I have never found an example of a Yangtze-river sampan with a white-painted bamboo canopy. I think this comment refers more to the Shanghai “Hongtou” sampan – but more about that later.

Close-up of the bamboo matting.

Earlier on you will recall I mentioned that there are two primary groups of sampans – the Ning-pang, manned by Ningpo men, and the Soo-pang, manned by either Soochow men, men of Shanghai, or men from Kiangyin, a small town some 80 miles up the Yangtze.

You will also recall that Worcester cited the mounting position of the load bearing-pin as a distinguishing feature. On the Ningpo-craft the bearing-pin for the yuloh is situated on the port side, which necessitates the sculler using his left hand on the oar; while in the boats operated by Soochow, Shanghai, and Kiangyin men, the bearing-pin is on the starboard side and the sculler operates the yuloh with his right hand.

There is, however, one more difference. Unlike the sampanmen from the other three localities, Ningpo men never take their wives and families afloat. It is astonishing that so small an area can constitute a permanent home for two adults and several children. If the family live on board, they also stow themselves away in this small space during working hours. In the fore compartment are stored the bedding, clothing, provisions, oil, charcoal, and extra cooking utensils. The wives and even the children of these sampan-dwellers can take their turn at the yuloh. The Soo-pang women scornfully maintain that one reason why the women of Ningpo do not live afloat is that they suffer from seasickness and are unhandy in a boat.

One of my favorite pictures of ancient times aboard a sampan.

And that my dear friends brings us to a close of tonight's posting. I want to thank each and everyone of you who has looked in on this build. It is sincerely appreciated.

Kindest regards - Heinrich

[that] they have learnt how to tread the wave from childhood.

boiling the crab as main food instead of grains,

using manila hemp instead of yarn to make garments.

children were assigned to cut the wild cane secretly,

when tides rising during spring nights

and the shallows are drown[ed].” (sic)

(Yang1,1154)

Hello Everyone

As promised in my previous posting, the bamboo canopy was next. It consisted of two main frames (each comprising of three separate sections) which are glued together and then further affixed by two overlapping sections which are appropriately curved.

The three separate sections which make up one frame and the two overlapping pieces (here unfortunately blocked by the clothes’ pegs) which lock them together. These two assembled frames are then inserted into four slots which are provided for in the top railing.

This was really an easy task and fitment of the two frames into the slots were perfect. However, here I deviated slightly from the kit plans. Have a look at the picture below

Unicorn suggests that the frames should be inserted into the slots up to the black line. The two slots directly above that line will thus stand proud of the top railing. This is understandable as there are 6 cross bars provided which slot into these six slots and which connect the two frames. However, I inserted my two frames up to the red line. This meant that my top railing would take the place of the first two bars which meant a much stronger connection and that the canopy would sit slightly deeper/lower than indicated on the plans. I was OK with this, and in the end, it turned out to be a very good move with an unexpected advantage.

Here the framework of the canopy is completed. Note the two extra spars directly in front of the framework which I did not have to use. Also notice the table in the living area. It looks very rudimentary but that is exactly what they looked like – low in height and devoid of any kind of decoration.

The installation of the bamboo canopy is an exercise in dexterity. It comes supplied in two separate, but identical sheets which needs to be glued back-to-back and then shaped to the correct form and size. This was easy enough, but then I made a mistake – I left it overnight to dry. If ever you have to work with bamboo and do something similar – use your PVA, wait an hour for it to set and while the glue is still pliable, do the bending. The problem is that once the glue is dry, those two sheets become surprisingly stiff and resist bending. Great care has to be taken that it doesn’t develop cracks in the shaping process – if that happens you are screwed, because the cracks will just get bigger and bigger.

I had two small cracks develop (ok…ok, I know…personally, I probably have many large cracks – but I’m referring to the bamboo piece now). Luckily, I did still have the bamboo sheeting from the first model. I just cut two appropriately-sized pieces and carefully glued them to the inside of the canopy where the cracks were starting to rear their ugly heads. That solved that little issue once and for all.

Next, I soaked the bamboo sheeting in water and curved it around one of my favorite objects – a Nescafe

Bamboo canopy in place. You will also notice six H-shaped frames - two at the stern and four in front of the canopy. The connecting piece on the starboard side (closest to the camera) has not yet been glued down, but has just been placed into position. The framework in front of the canopy was used for fish nets and the two “paddle oars” (different oars to the Yuloh).

Copyright by John S. Murray (I have no idea where I downloaded this picture from.)

The one at the stern was primarily used for storing the Yuloh and excess rope not in use. Both set of frames could also be used for a host of other things – anything from clothes lines to additional sheltering.

Stern framework used for the storage of the rope and as a clothes line. Note that a piece of clothing was even attached to the yuloh to dry.

This picture shows the port side paddle oar in its storage place. The reason that I have kept the right side of the framework “open” at this stage is to facilitate easier working on the rigging.

This is also where my unexpected advantage of my lower canopy panned-out nicely. Notice how nicely the paddle oar clears the canopy – exactly like it does in real life. With the canopy installed as per the plans’ suggestion, it would have been too high for the paddle oar to be mounted like that.

Now let’s take a few looks at the canopy in real-life situations.

Worcester describes the canopy as follows: “The centre part is decked, leaving a cockpit amidships which is covered with a small house made of closely woven matting arranged in three overlapping sections and painted white*. In this portion the passengers are accommodated, and actually as many as five can be carried and even more; nine, however, is about the limit.

*In all my research, I have never found an example of a Yangtze-river sampan with a white-painted bamboo canopy. I think this comment refers more to the Shanghai “Hongtou” sampan – but more about that later.

Close-up of the bamboo matting.

Earlier on you will recall I mentioned that there are two primary groups of sampans – the Ning-pang, manned by Ningpo men, and the Soo-pang, manned by either Soochow men, men of Shanghai, or men from Kiangyin, a small town some 80 miles up the Yangtze.

You will also recall that Worcester cited the mounting position of the load bearing-pin as a distinguishing feature. On the Ningpo-craft the bearing-pin for the yuloh is situated on the port side, which necessitates the sculler using his left hand on the oar; while in the boats operated by Soochow, Shanghai, and Kiangyin men, the bearing-pin is on the starboard side and the sculler operates the yuloh with his right hand.

There is, however, one more difference. Unlike the sampanmen from the other three localities, Ningpo men never take their wives and families afloat. It is astonishing that so small an area can constitute a permanent home for two adults and several children. If the family live on board, they also stow themselves away in this small space during working hours. In the fore compartment are stored the bedding, clothing, provisions, oil, charcoal, and extra cooking utensils. The wives and even the children of these sampan-dwellers can take their turn at the yuloh. The Soo-pang women scornfully maintain that one reason why the women of Ningpo do not live afloat is that they suffer from seasickness and are unhandy in a boat.

One of my favorite pictures of ancient times aboard a sampan.

And that my dear friends brings us to a close of tonight's posting. I want to thank each and everyone of you who has looked in on this build. It is sincerely appreciated.

Kindest regards - Heinrich

Hans Groenenberg

Forum veteraan

Of een ark.In Nederland wonen ook enkele mensen op een boot.

Dit noemen ze een "woonboot"

Bekijk bijlage 450746

Gentlemen

@Pingu57 Beste Peter - Gelukkig is daar baie plaatjes beskikbaar van de sampan, maar snaaks genoeg is die meeste van hulle geneem deur Westerlinge. Hoe gaat de oude saying: "A prophet is never honored in his own country".

@*Hans* My dearest Hans - your contributions will never "pollute" the log - no worries. Dit is belangrijke bydraes. Fotos is circa 1900.Ik is bewus van al deze woonbote in the Netherlands - in Afrikaans, they are called "huisbote".

@Hans Groenenberg - Jij laat my breed smile, Hans! Ons is nouw op dag 3 van Typhoon Fireworks hier in Nantong. De afgelope twee dae is alle klasse gekanselleer en vannacht is stormagtig. Dus het ik en de admiraal maar 4-uur vanmore opgestaan. De admiraal is nouw op pad werk toe want de dreineringstelsel in de city is haar verantwoordelikheid. Ik het nouw "naweek"!

@Pingu57 Beste Peter - Gelukkig is daar baie plaatjes beskikbaar van de sampan, maar snaaks genoeg is die meeste van hulle geneem deur Westerlinge. Hoe gaat de oude saying: "A prophet is never honored in his own country".

@*Hans* My dearest Hans - your contributions will never "pollute" the log - no worries. Dit is belangrijke bydraes. Fotos is circa 1900.Ik is bewus van al deze woonbote in the Netherlands - in Afrikaans, they are called "huisbote".

@Hans Groenenberg - Jij laat my breed smile, Hans! Ons is nouw op dag 3 van Typhoon Fireworks hier in Nantong. De afgelope twee dae is alle klasse gekanselleer en vannacht is stormagtig. Dus het ik en de admiraal maar 4-uur vanmore opgestaan. De admiraal is nouw op pad werk toe want de dreineringstelsel in de city is haar verantwoordelikheid. Ik het nouw "naweek"!

Hello Everyone

We continue ...

Earlier someone on SOS said that he is very interested in Tung Oil as a finish and I promised him that in the next posting, that will be covered. After everything that had to be glued, had been glued (no glue will adhere to a surface that is covered by 100% Tung Oil), I could start the process.

What is Tung Oil?

Tung oil is the oil from the seeds of a tree that originates in China (Aleuritis fordii and Aleuritis montana). The fruit of this tree that is 12 m (A. fordii) or 20 m (A. montana) in height contain 3–5 seeds. The seeds have a hard shell and contain ∼50% fat in their kernels. Despite its limited accessibility, tung oil is a favorite among furnishings due to its environment-friendly and versatile use. (Source: https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/tung-oil)

The seeds of the Tung tree.

However, applying Tung oil correctly, is a long, drawn-out process. It can take up to two days for each coat to harden, and depending on the wood and finish that you want, you may need at least 5 to 7 coats before you can have a protective durable finish. After that, regular reapplication is required once every week for a month and then once every month for a year, and later, from the second year onwards, once every year. The result is a beautiful, honey-like finish (again depending on the wood and the Tung oil.)

Tung Oil meets the Sampan:

Brown "gold". I am extremely fortunate in that I do not have to rely on commercially available tung, but that I have a contact who can supply me with the 100% pure variety without any preserving additives.

I started off by diluting the Tung Oil with mineral turpentine in a ratio of 40:60. The thinner mixture will allow the oil to penetrate better into the wood, while the turpentine aids in evaporation. The mixture can be applied with a natural bristle brush or sponge or a clean cotton rag. Using these methods eliminate any unnecessary “lines” forming on the wood.

It is important to start with those places that are hard to reach or largely invisible to the eye. If any boo-boo occurs, it can be rectified immediately and once done, those places do not have to be reached again later. In this case it meant that the sleeping cabin (the part covered by the canopy), the fish tank and the storage spaces were done first. The oil is applied in the direction of the wood to ensure that it saturates the wood as much as it can. The first coat must be applied liberally, and spread evenly. Look out that there are no puddles – if that is the case, dab those areas immediately with a Kleenex, tissue or anything that will absorb the moisture.

As soon as the first coat is dry (in my case it took less than two hours), apply the second in the same way with the same mixture. Now leave to dry overnight. This is where the following tip comes into play. Leave the tung oil / turpentine mixture open during the night as well. During the night, the turpentine content will evaporate further, automatically changing the ratio of the mixture to one more biased towards the oil.

The above four pictures show the sampan after the application of the first two coats. Now it will stand overnight and tomorrow I will continue.

Vriendelijke groete - Heinrich

We continue ...

Earlier someone on SOS said that he is very interested in Tung Oil as a finish and I promised him that in the next posting, that will be covered. After everything that had to be glued, had been glued (no glue will adhere to a surface that is covered by 100% Tung Oil), I could start the process.

What is Tung Oil?

Tung oil is the oil from the seeds of a tree that originates in China (Aleuritis fordii and Aleuritis montana). The fruit of this tree that is 12 m (A. fordii) or 20 m (A. montana) in height contain 3–5 seeds. The seeds have a hard shell and contain ∼50% fat in their kernels. Despite its limited accessibility, tung oil is a favorite among furnishings due to its environment-friendly and versatile use. (Source: https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/tung-oil)

The seeds of the Tung tree.

However, applying Tung oil correctly, is a long, drawn-out process. It can take up to two days for each coat to harden, and depending on the wood and finish that you want, you may need at least 5 to 7 coats before you can have a protective durable finish. After that, regular reapplication is required once every week for a month and then once every month for a year, and later, from the second year onwards, once every year. The result is a beautiful, honey-like finish (again depending on the wood and the Tung oil.)

Tung Oil meets the Sampan:

Brown "gold". I am extremely fortunate in that I do not have to rely on commercially available tung, but that I have a contact who can supply me with the 100% pure variety without any preserving additives.

I started off by diluting the Tung Oil with mineral turpentine in a ratio of 40:60. The thinner mixture will allow the oil to penetrate better into the wood, while the turpentine aids in evaporation. The mixture can be applied with a natural bristle brush or sponge or a clean cotton rag. Using these methods eliminate any unnecessary “lines” forming on the wood.

It is important to start with those places that are hard to reach or largely invisible to the eye. If any boo-boo occurs, it can be rectified immediately and once done, those places do not have to be reached again later. In this case it meant that the sleeping cabin (the part covered by the canopy), the fish tank and the storage spaces were done first. The oil is applied in the direction of the wood to ensure that it saturates the wood as much as it can. The first coat must be applied liberally, and spread evenly. Look out that there are no puddles – if that is the case, dab those areas immediately with a Kleenex, tissue or anything that will absorb the moisture.

As soon as the first coat is dry (in my case it took less than two hours), apply the second in the same way with the same mixture. Now leave to dry overnight. This is where the following tip comes into play. Leave the tung oil / turpentine mixture open during the night as well. During the night, the turpentine content will evaporate further, automatically changing the ratio of the mixture to one more biased towards the oil.

The above four pictures show the sampan after the application of the first two coats. Now it will stand overnight and tomorrow I will continue.

Vriendelijke groete - Heinrich