Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Nota: This feature may not be available in some browsers.

Je gebruikt een verouderde webbrowser. Het kan mogelijk deze of andere websites niet correct weergeven.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

IZj : mijn home made F5J

- Topicstarter jacobbos

- Startdatum

Jaaa, ben blij dat ik wel een ander deel gebouwd heb. Je zou de hele vleugel zo moeten bouwen...

En die capstrips op de voorzijde is dan puur optisch want dat deel is al torsiestijf genoeg van zichzelf, dus gaan we niet doen

Tja, ik weet dat er onder jullie zijn die hetzelfde doen wat ik net even een kwartiertje gedaan heb, gewoon kijken naar wat je gemaakt heb. Lekker hoor!!

En nu door met de tekening van de vleugel, is een heel gestoei, maar wel leuk en leerzaam!

Groet,

Jacob

En die capstrips op de voorzijde is dan puur optisch want dat deel is al torsiestijf genoeg van zichzelf, dus gaan we niet doen

Tja, ik weet dat er onder jullie zijn die hetzelfde doen wat ik net even een kwartiertje gedaan heb, gewoon kijken naar wat je gemaakt heb. Lekker hoor!!

En nu door met de tekening van de vleugel, is een heel gestoei, maar wel leuk en leerzaam!

Groet,

Jacob

DirkSchipper

Forum veteraan

Top man!

Dank Dirk!

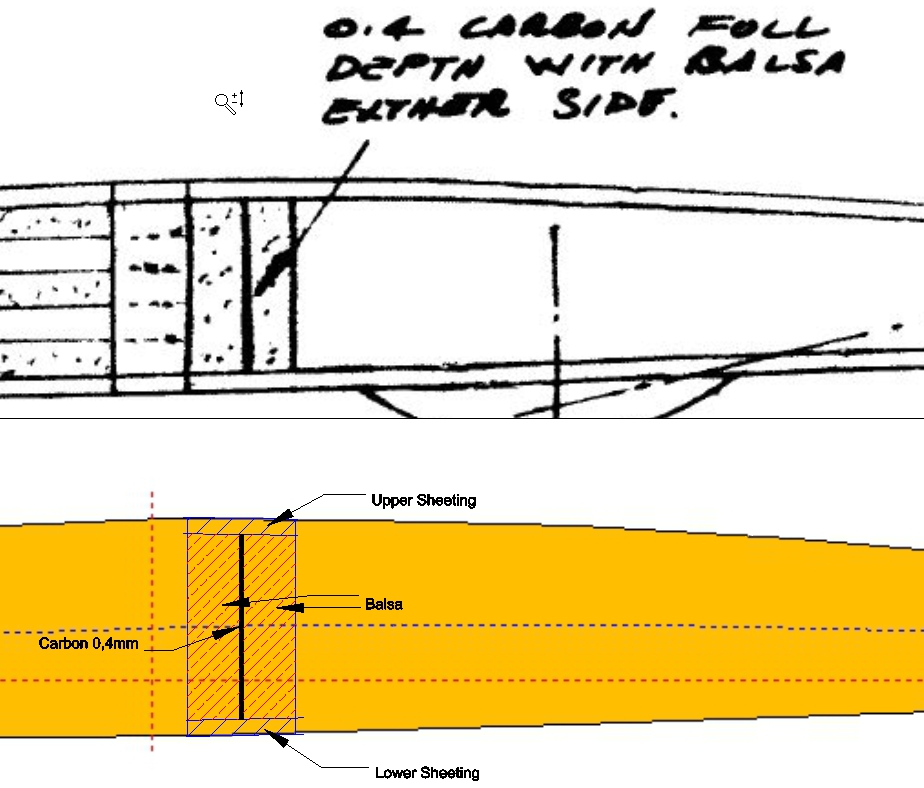

Volgende uitdaging is dus de vleugel en op dit moment stoei ik wat met de ligger zoals Brian Austin die op tekening heeft staan en, naar ik aanneem, gebruikt heeft. Gevoelsmatig is me die wat te licht. Ik heb hem een mail gezonden met wat vragen en de strekking daarvan staat in de schets/tekening die ik gemaakt heb:

Boven zie je een deel van de originele tekening, daaronder mijn overgetrokken stukje. Het lijkt er op dat hij de ligger in het middendeel alleen opbouwt uit een 0,4mm koolstof strip wat ingedekt is in balsa. Zoals gezegd kriebelt dat bij mij. Ik zou daar 2 horizontale koolstof-strips aan boven- en onderzijde aan toe willen voegen zodat er een H-balk ontstaat (90 graden gekanteld). Wat denken jullie?

Groet,

Jacob

En even heel iets anders: wat leer je veel van zo'n project als dit. Het viel me ineens op dat ik handig wordt met DraftSight, dat DevWing steeds leuker word, dat ik conversies van JPG naar PDF en vice versa uitvoer, met gedeeltes van een Printscreen ga toveren, etc.

Volgende uitdaging is dus de vleugel en op dit moment stoei ik wat met de ligger zoals Brian Austin die op tekening heeft staan en, naar ik aanneem, gebruikt heeft. Gevoelsmatig is me die wat te licht. Ik heb hem een mail gezonden met wat vragen en de strekking daarvan staat in de schets/tekening die ik gemaakt heb:

Boven zie je een deel van de originele tekening, daaronder mijn overgetrokken stukje. Het lijkt er op dat hij de ligger in het middendeel alleen opbouwt uit een 0,4mm koolstof strip wat ingedekt is in balsa. Zoals gezegd kriebelt dat bij mij. Ik zou daar 2 horizontale koolstof-strips aan boven- en onderzijde aan toe willen voegen zodat er een H-balk ontstaat (90 graden gekanteld). Wat denken jullie?

Groet,

Jacob

En even heel iets anders: wat leer je veel van zo'n project als dit. Het viel me ineens op dat ik handig wordt met DraftSight, dat DevWing steeds leuker word, dat ik conversies van JPG naar PDF en vice versa uitvoer, met gedeeltes van een Printscreen ga toveren, etc.

Laatst bewerkt:

PH_AJH

Forum veteraan

Voor wat ik er van begrepen heb....de buiging in een vleugel kan alleen ontstaan als de boven- en onderhuid van je vleugel van elkaar af bewegen. De webbing die je normaal gesproken kops tussen de liggers lijmt heeft precies die functie, en die geeft ook de stijfheid. Niet de buigstijfheid van de liggers zelf! Die strip carbon tussen 2 lagen balsa als webbing maakt dat je het balsa echt niet meer uit elkaar kunt trekken. Twee strippen er boven- en onderop voegt naar mijn idee niks toe want bij een H-profiel zorgen die voor stijfheid haaks op de ligger maar die heb je hier al door de boven- en onderhuid van je vleugel. Lijkt mij een hele goede methode.....

Rick NL

PH-SAM

De carbon webbing is niet (alleen) om de gordingen (horizontale strippen) van de ligger bij elkaar te houden en uitbuiging te voorkomen. Daarvoor zou alleen kops balsa voldoende zijn.

Omdat er in de onderste gording trekkracht staat en in de bovenste drukkracht leveren de gordingen een schuifkracht op de webbing. Hiervoor is de koolstof, liefst onder 45°, verantwoordelijk. De sterkte is voldoende als ze door de balsa vlak wordt gehouden.

In de getoonde konstruktie werkt de huid als gording, wat mij vrij matig toeschijnt. Ik zou daar graag echte 'horizontale strippen' van vuren of koolstof zien. Ik voel dus met je mee, Jacob.

Rick

Omdat er in de onderste gording trekkracht staat en in de bovenste drukkracht leveren de gordingen een schuifkracht op de webbing. Hiervoor is de koolstof, liefst onder 45°, verantwoordelijk. De sterkte is voldoende als ze door de balsa vlak wordt gehouden.

In de getoonde konstruktie werkt de huid als gording, wat mij vrij matig toeschijnt. Ik zou daar graag echte 'horizontale strippen' van vuren of koolstof zien. Ik voel dus met je mee, Jacob.

Rick

Je hebt eigenlijk een I-ligger nodig zoals metaal in woningbouw.

Hierbij is voor de buigsterkte het boven en onder horizontale gedeelte van belang voor rek en druk. En de de ziel ( in ons geval de webbings bestaand uit kops balsa al dan niet met 1 of meerdere lagen carbon). Alles moet goed aan mekaar verlijmd zijn om een stevig geheel te vormen en de schuifkrachten op te vangen. Het is ook van belang dat de bovenste horizontale strippen voldoende dik en stijf zijn omdat daar drukkrachten optreden en het meeste materiaal daar minder drukweerstand kan opvangen in vergelijk met de onderste strip die hoofdzakelijk op rek belast wordt bij positieve belasting.

De horizontale strippen moeten hierbij met de vezels in de langsrichting liggen. Hiervoor gebruikt men unidirectioneel carbon of houten liggertjes.

Willy

Hierbij is voor de buigsterkte het boven en onder horizontale gedeelte van belang voor rek en druk. En de de ziel ( in ons geval de webbings bestaand uit kops balsa al dan niet met 1 of meerdere lagen carbon). Alles moet goed aan mekaar verlijmd zijn om een stevig geheel te vormen en de schuifkrachten op te vangen. Het is ook van belang dat de bovenste horizontale strippen voldoende dik en stijf zijn omdat daar drukkrachten optreden en het meeste materiaal daar minder drukweerstand kan opvangen in vergelijk met de onderste strip die hoofdzakelijk op rek belast wordt bij positieve belasting.

De horizontale strippen moeten hierbij met de vezels in de langsrichting liggen. Hiervoor gebruikt men unidirectioneel carbon of houten liggertjes.

Willy

Dank voor de snelle reacties!

Ondertussen heeft Brian ook al een mail gezonden met nadere uitleg, het is inderdaad zo dat op de tekening de horizontale delen missen. De volgende constructie heeft Brian toegepast:

Hij heeft de horizontale koolstof delen opgebouwd uit 2 strips van 0,6 mm dik en 10 mm breed omdat hij op dat moment de 1,0 mm dikte die hij wilde gebruiken niet kon kopen. (maatvoering is nog foutief in de tekening hierboven...) Brian wees mij op 2 sites gevonden waar mooi materiaal te koop is: 1 in Nederland en 1 in de UK.

We puzzelen lekker verder. Ik ga nu mijn materiaallijst samenstellen, pas nadat ik 100% zeker weet dat het materiaal aanwezig is en onderweg pas ik de tekening en DevWing aan met de definitieve maatvoering zodat dan de ribben gefreesd kunnen worden.

Groet,

Jacob

Ondertussen heeft Brian ook al een mail gezonden met nadere uitleg, het is inderdaad zo dat op de tekening de horizontale delen missen. De volgende constructie heeft Brian toegepast:

Hij heeft de horizontale koolstof delen opgebouwd uit 2 strips van 0,6 mm dik en 10 mm breed omdat hij op dat moment de 1,0 mm dikte die hij wilde gebruiken niet kon kopen. (maatvoering is nog foutief in de tekening hierboven...) Brian wees mij op 2 sites gevonden waar mooi materiaal te koop is: 1 in Nederland en 1 in de UK.

We puzzelen lekker verder. Ik ga nu mijn materiaallijst samenstellen, pas nadat ik 100% zeker weet dat het materiaal aanwezig is en onderweg pas ik de tekening en DevWing aan met de definitieve maatvoering zodat dan de ribben gefreesd kunnen worden.

Groet,

Jacob

DirkSchipper

Forum veteraan

Die carbon webbing in het midden wordt heel vaak geadviseerd juist niet van carbon te maken, maar van glas.

Wat wel heel belangrijk is, is dat de vezel van die webbing onder 45x45 graden staan.

Het waarom:

- de webbing moet voorkomen dat een buiging van de ligger (bij een positieve belasting) de bovenste cap-strip naar buiten schuift tov. de onderste. Om die verschuiving tegen te gaan zijn vezels onder 45x45 gr. het beste. Je zou overigens net zo hard kunnen zeggen dat de onderste cap-strip naar binnen wil ....

- de schuifkrachten die door de webbing tegengewerkt moeten worden zijn (pakweg) een factor 10 kleiner dan de trek- en drukkrachten in de cap-strips. Glas is dus voldoende.

- met carbon als midden-webbing krijg je weliswaar een stijvere ligger die minder buigt. Maar het breekpunt blijft bij dezelfde optredende kracht optreden (als de webbing niet het zwakste punt is tenminste). Met glas is je ligger iets flexibeler, waardoor je de buiging ziet! Dat zorgt ervoor dat je bij zware belasing iets minder aan de up trekt. Dat zou je zomaar een gebroken ligger kunnen schelen.

Wat wel heel belangrijk is, is dat de vezel van die webbing onder 45x45 graden staan.

Het waarom:

- de webbing moet voorkomen dat een buiging van de ligger (bij een positieve belasting) de bovenste cap-strip naar buiten schuift tov. de onderste. Om die verschuiving tegen te gaan zijn vezels onder 45x45 gr. het beste. Je zou overigens net zo hard kunnen zeggen dat de onderste cap-strip naar binnen wil ....

- de schuifkrachten die door de webbing tegengewerkt moeten worden zijn (pakweg) een factor 10 kleiner dan de trek- en drukkrachten in de cap-strips. Glas is dus voldoende.

- met carbon als midden-webbing krijg je weliswaar een stijvere ligger die minder buigt. Maar het breekpunt blijft bij dezelfde optredende kracht optreden (als de webbing niet het zwakste punt is tenminste). Met glas is je ligger iets flexibeler, waardoor je de buiging ziet! Dat zorgt ervoor dat je bij zware belasing iets minder aan de up trekt. Dat zou je zomaar een gebroken ligger kunnen schelen.

arjan191

Vriend van modelbouwforum.nl

Ik heb de tekeningen van de Watts New ook gekocht, en ga die bouwen met jouw diagonale ribben en capstrips er in. De I-profiel constructie heb ik hem ook gevraagd na bestudering van de tekening, waarop hij inderdaad bevestigend antwoordde. Ik heb hem ook gevraagd over glas vs carbon voor de staander in het I-profiel. Daarop gaf hij aan dat hij die constructie al jaren gebruikt en er op dat punt nooit schade is ontstaan tgv carbon in de ligger, terwijl het toestel (3,1m) met draaiende motor (tgv storing in regelaar) en dito hoge snelheid enorm op zn donder heeft gehad:

"In respect to the view as to the strength of the carbon shear web over the woven glass cloth method, there is more flex on the carbon or the glass cloth method, than on the standard moulded models that I have had experience of over the years.

Have used this method over some 12 years now, with no failures of the wing. When I was first setting the Watts New up a couple of years back, for crow breaking, I had the ailerons deflecting up to early. This coupled to the speed on one approach caused the wing to flew violently down into anhedral, but did not result in any damage.

As an add on to the above, another more frightening incident some 8 years, endorses this. I made an extended wing for the Watts Up model that you maybe aware of. This was 3.1 metres span and used the carbon shear web between 10X3mm spruce spars. One evening whilst sport flying the altimeter switch, failed for some reason, which caused me to be unable to switch the motor off!!!!!!!!!

The model became almost uncontrollable due to the speed being such that in trying to get it down made the speed build up even more. This led to the wing tip let breaking off, which made flying even more difficult, as you can imagine. I finally managed to land it OK, with the motor smoking away, after the BEC cut in. Think this exposed the construction of this type to stresses far and away greater than would be experienced under normal flying."

"In respect to the view as to the strength of the carbon shear web over the woven glass cloth method, there is more flex on the carbon or the glass cloth method, than on the standard moulded models that I have had experience of over the years.

Have used this method over some 12 years now, with no failures of the wing. When I was first setting the Watts New up a couple of years back, for crow breaking, I had the ailerons deflecting up to early. This coupled to the speed on one approach caused the wing to flew violently down into anhedral, but did not result in any damage.

As an add on to the above, another more frightening incident some 8 years, endorses this. I made an extended wing for the Watts Up model that you maybe aware of. This was 3.1 metres span and used the carbon shear web between 10X3mm spruce spars. One evening whilst sport flying the altimeter switch, failed for some reason, which caused me to be unable to switch the motor off!!!!!!!!!

The model became almost uncontrollable due to the speed being such that in trying to get it down made the speed build up even more. This led to the wing tip let breaking off, which made flying even more difficult, as you can imagine. I finally managed to land it OK, with the motor smoking away, after the BEC cut in. Think this exposed the construction of this type to stresses far and away greater than would be experienced under normal flying."